- Home Page

- Company Profile

-

Our Products

- FRP Prefabricated Structure

- Prefabricated Structure

- Security Cabin

- Prefabricated Labor Colony

- Workmen Colony

- Security Cabin

- Porta Toilets

- Vending Shop

- Prefab Toilet

- Prefabricated Modular Hospital Building

- Prefabricated Bunk House

- Portable Office Cabin

- Pharma Clean Room

- Prefabricated Security Cabin

- Lift & Shift Shelters

- Prefabricated Portable Cabin

- Insulated Storage Building

- Staff Quarters

- Weekend Homes (1/2/3 BHK)

- Factory Building / Office

- Prefabricated Workers Colony

- Relocatable Site Office Building

- Prefab Cold Room

- Factory Building

- G+1 Colony Prefabricated structure

- Hospital Building

- Insulated Storage Building

- Lift & Shift Shelter

- Prefab Arogyavan Project

- Project Office

- Relocatable Site Office

- SGB Project

- Staff Quarters

- Weekend Home

- Workman Colony

- PHARMA CLEAN ROOM

- COLD STORAGE ROOMS

- FACTORY BUILDING Prefabricated

- G Plus 1 Colony Prefabricated

- HOSPITAL BUILDING

- INSULATED STORAGE BUILDING

- Lift and Shift Shelter

- Prefab Project

- Prefab Toilet

- Project Office

- RELOCATABLE SITE OFFICE BUILDING

- Security Cabin

- Project Executed

- Staff Quarters Prefabricated

- WEEKEND HOMES (1-2-3 BHK)

- Workman Colony Prefabricated Structure

- Ventilating Systems

- PUF Panel

- PUF Insulated Cabins

- Cold Storage Room

- Polycarbonate Multiwall Sheet

- Polycarbonate Sheet

- Solid And Textured Polycarbonate Roofing Sheets

- uPVC Sheet

- Prefab Products

- PHARMA CLEAN ROOM

- COLD STORAGE ROOMS

- FACTORY BUILDING OFFICE

- G Plus 1 Colony

- HOSPITAL BUILDING

- INSULATED STORAGE BUILDING

- Lift And Shift Shelter

- Prefab Project

- Prefab Toilet

- Project Office

- RELOCATABLE SITE OFFICE BUILDING

- Security Cabin

- Project Executed

- Staff Quarters

- WEEKEND HOMES (1 2 3 BHK)

- Workman Colony

- Extra Links

- Contact Us

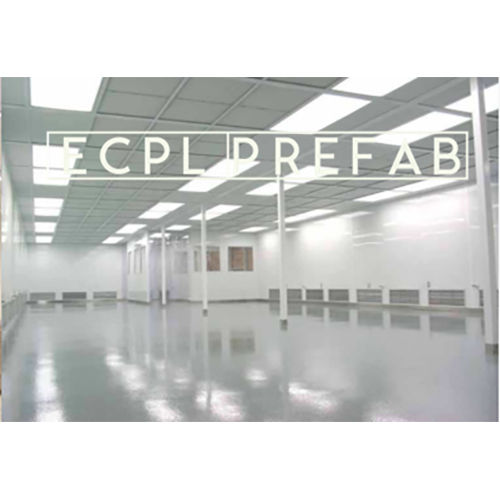

PHARMA CLEAN ROOM

MOQ : 100 Square Foots

PHARMA CLEAN ROOM Specification

- Life Span

- More than 20 Years

- Open Style

- Sliding

- Dimension (L*W*H)

- Customized as per requirement

- Window Material

- Powder Coated Aluminum

- Door Material

- Aluminum with Glass

- Connection

- Bolt Connection

- Insulation

- Polyurethane Foam

- Wall Materials

- Sandwich PUF Panel

- Material

- Other

- Roof Material

- Prepainted GI Sheet

- Thickness Of Wall Panel

- 50 mm to 100 mm

- Door

- Swing/Sliding

- Window

- Double Glazed Fixed

- Window Style

- Fixed

- Floor Material

- Epoxy Coated Concrete

- Floor Load

- 500 kg/m

- Roof Dead Load

- 30 kg/m

- Roof Live Load

- 50 kg/m

- Earthquake Intensity

- 8 Grade

- Color

- White

- Use

- Warehouse, Plant

- Power Supply

- 220V/415V AC, 50Hz Single/Three Phase

- Relative Humidity

- 45% - 65%

- Lighting Type

- Flush Mounted LED

- Sealing System

- Silicone Gasket for Doors and Windows

- Air Change Rate

- 20-30 Per Hour

- Fire Resistance

- Up to 2 Hours

- Floor Cove Radius

- 50mm for Easy Cleaning

- Temperature Range

- 18°C - 25°C

- Ventilation System

- Integrated HVAC with AHU Controls

- Panel Surface Finishing

- Antibacterial Coating

- Clean Room Classifications

- Class 100, Class 1000, Class 10000, Class 100000

- Sound Insulation

- Up to 40 dB

- Air Filtration

- HEPA Filters 99.97% @ 0.3 micron

- Wall Jointing

- Cam-lock System

PHARMA CLEAN ROOM Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 10000 Square Foots Per Day

- Delivery Time

- 1 Week

About PHARMA CLEAN ROOM

The walls of Modular Partition clean rooms are a composite construction, which is made using two skins of high pressure Stainless and Precoated Galvanized Iron framework with a sealed and insulated interior. You can get additional wall heights using a stacking technique. The walls panel of a modular clean room are properly sealed with a flush finish by the SS framework. The two skin layers of high pressure stainless & precoated galvanized iron are packed with insulation materials inside.

Features

- Easily Assemble

- Weather Resistance

- Low Maintanance

- Quick Installation

- Flexible Configurations.

- Easily Modified As Requirements Change.

- Low Design Costs.

- Prefabrication Decreases Build Time.

- Consistent Quality.

- Predictable Performance.

- Full Regulatory Compliance

Stringent Air Quality Management

Pharma Clean Rooms feature advanced HEPA filtration systems, achieving 99.97% efficiency at 0.3 microns. With air change rates of 2030 per hour, the environment remains free of contaminants, complying with regulatory standards for Class 100, 1000, 10000, and 100000 clean rooms. Integrated HVAC and AHU controls further optimize airflow and particulate control for pharmaceutical safety.

Hygienic and Durable Construction

Our clean rooms utilize antibacterial coated sandwich PUF panels, epoxy coated concrete floors, and prepainted GI sheet roofing, ensuring easy cleaning and resistance to microbial growth. Sealing with silicone gaskets and a 50mm cove radius enhances hygiene and maintenance, while robust construction ensures fire resistance up to 2 hours and earthquake intensity tolerance up to Grade 8.

Customized for Versatile Applications

With customizable dimensions, wall thickness (50100 mm), and versatile utility supply options (220V/415V AC), these clean rooms are suitable for warehouses, plants, and storage. The modular design, cam-lock wall jointing, and bolt connections offer quick assembly and long-term use, making them adaptable for various pharmaceutical operations across India.

FAQs of PHARMA CLEAN ROOM:

Q: How do Pharma Clean Rooms maintain a controlled environment for pharmaceutical use?

A: Pharma Clean Rooms utilize HEPA filters that capture 99.97% of airborne particles down to 0.3 microns, along with 2030 air changes per hour, precise temperature (18C25C), and humidity (45%65%) controls. Integrated HVAC and AHU ensure constant monitoring and adjustment to maintain required clean room classifications.Q: What are the benefits of the antibacterial coating and silicone gasket sealing system?

A: The antibacterial coating prevents microbial contamination on wall surfaces, while silicone gaskets on doors and windows provide airtight sealing. This dual system ensures higher hygiene, easier cleaning, and minimizes the risk of cross-contamination in pharmaceutical environments.Q: When is it necessary to select higher clean room classifications, such as Class 100 or 1000?

A: Class 100 or 1000 clean rooms are essential for processes that require extremely low levels of particulate contamination, such as the production of sterile pharmaceuticals, sensitive APIs, or high-precision research and development. They provide the strictest air quality controls available in clean room environments.Q: Where can these Pharma Clean Rooms be installed and are they customizable?

A: These clean rooms can be installed in pharmaceutical warehouses, production plants, storage facilities, or any environment requiring controlled air quality. Dimensions, wall thickness, and panel materials can be customized according to client requirements for optimal integration and performance.Q: What is the process for installing a Pharma Clean Room at my facility?

A: Installation involves site assessment, customization of dimensions and specifications, fabrication of modular panels (PUF sandwich), and on-site assembly using cam-lock and bolt connections. All systems including HVAC, lighting, and sealing are integrated for turnkey operation by our expert team.Q: How can the clean rooms epoxy coated concrete floors and 50mm floor cove radius aid in maintenance?

A: Epoxy coated concrete provides a seamless, chemical-resistant surface, reducing dust and bacterial accumulation. The 50mm cove radius facilitates the easy removal of debris and thorough cleaning, ensuring superior hygiene and compliance with pharmaceutical standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Prefabricated Structure Category

Project Executed

Price Range 250.00 - 1200.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Use : House

Material : Other

Color : Multicolour

Roof Material : Other, Galvanized Sheet

Insulated Storage Building

Use : Storage and logistics, Other

Material : Other , Steel reinforced concrete

Color : White

Roof Material : Other, Corrugated metal or reinforced concrete

Relocatable Site Office Building

Use : Other, Office Work

Material : Other , Steel Frame Structure

Color : White

Roof Material : Other, PU Sandwich Panel

Prefabricated Modular Hospital Building

Use : Other

Material : Other

Color : Blue and white

Roof Material : Other

|

EVEREST COMPOSITES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry