- Home Page

- Company Profile

-

Our Products

- FRP Prefabricated Structure

- Prefabricated Structure

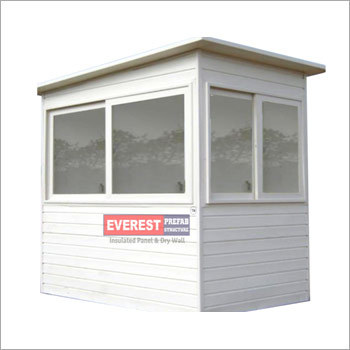

- Security Cabin

- Prefabricated Labor Colony

- Workmen Colony

- Security Cabin

- Porta Toilets

- Vending Shop

- Prefab Toilet

- Prefabricated Modular Hospital Building

- Prefabricated Bunk House

- Portable Office Cabin

- Pharma Clean Room

- Prefabricated Security Cabin

- Lift & Shift Shelters

- Prefabricated Portable Cabin

- Insulated Storage Building

- Staff Quarters

- Weekend Homes (1/2/3 BHK)

- Factory Building / Office

- Prefabricated Workers Colony

- Relocatable Site Office Building

- Prefab Cold Room

- Factory Building

- G+1 Colony Prefabricated structure

- Hospital Building

- Insulated Storage Building

- Lift & Shift Shelter

- Prefab Arogyavan Project

- Project Office

- Relocatable Site Office

- SGB Project

- Staff Quarters

- Weekend Home

- Workman Colony

- PHARMA CLEAN ROOM

- COLD STORAGE ROOMS

- FACTORY BUILDING Prefabricated

- G Plus 1 Colony Prefabricated

- HOSPITAL BUILDING

- INSULATED STORAGE BUILDING

- Lift and Shift Shelter

- Prefab Project

- Prefab Toilet

- Project Office

- RELOCATABLE SITE OFFICE BUILDING

- Security Cabin

- Project Executed

- Staff Quarters Prefabricated

- WEEKEND HOMES (1-2-3 BHK)

- Workman Colony Prefabricated Structure

- Ventilating Systems

- PUF Panel

- PUF Insulated Cabins

- Cold Storage Room

- Polycarbonate Multiwall Sheet

- Polycarbonate Sheet

- Solid And Textured Polycarbonate Roofing Sheets

- uPVC Sheet

- Prefab Products

- PHARMA CLEAN ROOM

- COLD STORAGE ROOMS

- FACTORY BUILDING OFFICE

- G Plus 1 Colony

- HOSPITAL BUILDING

- INSULATED STORAGE BUILDING

- Lift And Shift Shelter

- Prefab Project

- Prefab Toilet

- Project Office

- RELOCATABLE SITE OFFICE BUILDING

- Security Cabin

- Project Executed

- Staff Quarters

- WEEKEND HOMES (1 2 3 BHK)

- Workman Colony

- Extra Links

- Contact Us

Project Executed

MOQ : 100 Square Foots

Project Executed Specification

- Door Material

- Steel

- Life Span

- 15 Years

- Open Style

- Sliding

- Window Material

- Aluminium

- Insulation

- EPS

- Wall Materials

- EPS Cement Board

- Connection

- Bolt Connection

- Dimension (L*W*H)

- 5800*2200*2400mm

- Material

- Other

- Roof Material

- Galvanized Sheet

- Thickness Of Wall Panel

- 75mm

- Door

- Security Door

- Window

- Double Glass

- Window Style

- Sliding

- Floor Material

- Cement Board

- Floor Load

- 150 Kg/m2

- Roof Dead Load

- 30 Kg/m2

- Roof Live Load

- 50 Kg/m2

- Earthquake Intensity

- Grade 8

- Color

- Multicolour

- Use

- House

- Wall Panel Type

- Sandwich Panel

- Fire Resistance

- Class B1

- Humidity Resistance

- Yes

- Surface Finish

- Smooth Paint

- Wind Resistance

- Grade 11

- Sound Insulation

- Good

- Interior Finish

- Customizable

- External Wall Thickness

- 75mm

- Installation Time

- 1-3 Days

- Foundation

- Concrete

Project Executed Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 10000 Square Foots Per Day

- Delivery Time

- 1 Week

About Project Executed

Prefabricated construction takes half the time as compared to traditional on-site construction. This is because of better up-front planning, zero on-site weather disturbance, reduced site disturbance, and use of advanced construction techniques. This all enables construction companies/developers to take on multiple projects simultaneously, allowing these businesses to grow rather than putting all the focus and resources in a few projects.

Features

- Low Maintanance

- Quick Installation

- Cost Effective

- Economical

- Durable

- Easily Assembled

Robust Structural Safety

Engineered for superior fire (Class B1) and wind resistance (Grade 11), this pre-fabricated house is ideally suited for challenging environments. Its EPS cement board sandwich panel construction, steel doors, and double-glazed aluminium windows provide enhanced protection against fire, wind, and seismic activity up to Grade 8.

Customizable and Comfortable Living

Enjoy the flexibility of customizable interior finishes that suit your style and requirements. The smooth exterior multicolour paint and the EPS-insulated wall system deliver both aesthetic appeal and effective sound, humidity, and thermal insulation, creating a pleasant living environment year-round.

Fast Installation & Long-Term Durability

Set on a reliable concrete foundation with a robust galvanized steel roof, the house is designed for quick assembly (typically 1-3 days) and long-term use, with a 15-year lifespan and low maintenance. Its bolt connection system facilitates straightforward installation and potential relocation if needed.

FAQs of Project Executed:

Q: How is the fire and wind resistance of this house ensured?

A: The house uses 75mm thick EPS cement board sandwich panels that meet Fire Resistance Class B1 and Wind Resistance Grade 11 standards, ensuring dependable protection in fire-prone and high-wind environments.Q: What is the typical installation process and timeline for this house?

A: Installation is streamlined with bolt connections and prefabricated components, allowing the entire house to be assembled on a concrete foundation within 1 to 3 days by trained professionals.Q: Where can this modular house be installed?

A: The house is suitable for diverse locations across Indiaincluding urban, rural, or challenging climatic areasthanks to its humidity resistance, sound insulation, and robust foundation requirements.Q: What are the main benefits of using sandwich panel wall systems in this house?

A: Sandwich panels provide effective thermal and acoustic insulation, reliable fire resistance (Class B1), and ensure a lightweight yet sturdy structure, significantly enhancing comfort and safety indoors.Q: How customizable are the internal finishes of the house?

A: Interiors can be tailored to suit specific preferences, allowing homeowners to choose colours, materials, and layout modifications according to their needs and taste.Q: When is this structure appropriate for use as a house?

A: This modular house is ideal for permanent or temporary housing needs where quick installation, robust safety features, and customizable interiors are crucial, such as for workers accommodations, individual homes, or disaster-relief housing.Q: What is the maximum weight the floor can support, and how is structural integrity maintained?

A: The cement board floor supports up to 150 kg/m. Combined with a concrete foundation and EPS cement board walls, this ensures excellent structural integrity and safety for daily residential activities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Prefabricated Structure Category

Prefabricated Labor Colony

Use : Other, Labour Accommodation

Material : Other , Metal/Steel Structure

Color : White and Blue

Roof Material : Other, PPGI Sheet / Insulated Sandwich Panel

Relocatable Site Office

Use : Other, Office space

Material : Other , Steel structure

Color : White

Roof Material : Metal sheets with insulation, Other

Security Cabin

Minimum Order Quantity : 10 Units

Use : Office

Material : PU Panel, Steel, Aluminum sheet

Color : White

Roof Material : Steel

WEEKEND HOMES (1-2-3 BHK)

Minimum Order Quantity : 100 Square Foots

Use : House

Material : PU Panel

Color : White

|

EVEREST COMPOSITES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry