- Home Page

- Company Profile

-

Our Products

- FRP Prefabricated Structure

- Prefabricated Structure

- Security Cabin

- Workmen Colony

- Prefabricated Labor Colony

- Security Cabin

- Porta Toilets

- Vending Shop

- Prefabricated Modular Hospital Building

- Prefab Toilet

- Prefabricated Bunk House

- Portable Office Cabin

- Pharma Clean Room

- Lift & Shift Shelters

- Prefabricated Portable Cabin

- Prefabricated Security Cabin

- Insulated Storage Building

- Staff Quarters

- Weekend Homes (1/2/3 BHK)

- Factory Building / Office

- Prefabricated Workers Colony

- Relocatable Site Office Building

- Prefab Cold Room

- Factory Building

- G+1 Colony Prefabricated structure

- Hospital Building

- Insulated Storage Building

- Lift & Shift Shelter

- Prefab Arogyavan Project

- Project Office

- Relocatable Site Office

- SGB Project

- Staff Quarters

- Weekend Home

- Workman Colony

- PHARMA CLEAN ROOM

- COLD STORAGE ROOMS

- FACTORY BUILDING Prefabricated

- G Plus 1 Colony Prefabricated

- HOSPITAL BUILDING

- INSULATED STORAGE BUILDING

- Shift Shelter

- Prefab Project

- Prefab Toilet

- Project Office

- RELOCATABLE SITE OFFICE BUILDING

- Security Cabin

- Project Executed

- Staff Quarters Prefabricated

- WEEKEND HOMES (1-2-3 BHK)

- Workman Colony Prefabricated Structure

- Ventilating Systems

- PUF Panel

- PUF Insulated Cabins

- Cold Storage Room

- Polycarbonate Multiwall Sheet

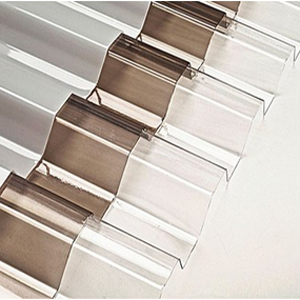

- Polycarbonate Sheet

- Solid And Textured Polycarbonate Roofing Sheets

- uPVC Sheet

- Prefab Products

- PHARMA CLEAN ROOM

- COLD STORAGE ROOMS

- FACTORY BUILDING OFFICE

- G Plus 1 Colony

- HOSPITAL BUILDING

- INSULATED STORAGE BUILDING

- Lift And Shift Shelter

- Prefab Project

- Prefab Toilet

- Project Office

- RELOCATABLE SITE OFFICE BUILDING

- Security Cabin

- Project Executed

- Staff Quarters

- WEEKEND HOMES (1 2 3 BHK)

- Workman Colony

- Extra Links

- Contact Us

Polycarbonate Sheet

Polycarbonate Sheet Specification

- Deflection

- High flexibility, minimal deflection under normal load

- Surface Finish

- Glossy / Embossed

- Max. Working Load

- High impact strength, over 200 times stronger than glass

- Product Type

- Solid Polycarbonate Sheet

- Material

- Polycarbonate

- Standard Thickness

- 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm

- Length

- 2440 mm

- Width

- 1220 mm

- Weight

- Approx. 1.2 kg/m (for 2 mm thickness)

- Dimension (L*W*H)

- 2440 mm x 1220 mm x (2-10 mm)

- Color

- Transparent, Opal, Bronze, Blue, Green, Customized

About Polycarbonate Sheet

Polycarbonate sheets are a type of thermoplastic polymer sheet that is widely used in a variety of applications due to their strength, durability, and transparency. They are made from a polycarbonate resin that is extruded into flat sheets, which can be cut to size and shaped as needed.Polycarbonate sheets are highly impact-resistant, making them ideal for use in areas where high levels of impact resistance are required. They are also highly resistant to UV radiation, which means that they will not yellow or degrade when exposed to sunlight over time.

Polycarbonate sheets are available in a variety of sizes, thicknesses, and colors, and can be custom fabricated to meet specific design requirements. They are easy to install and maintain, and can be cut to size using standard cutting tools.

Superior Performance in Extreme Conditions

These polycarbonate sheets are engineered to operate flawlessly within a temperature range of -40C to +120C, making them suitable for harsh environments. The material is resistant to acids and alkalis, while high impact strength and minimal deflection offer reliability under heavy loads. Their thermal conductivity is low, enhancing energy efficiency for glazing and roofing applications.

Flexible Application and Customization

Polycarbonate sheets can be utilized for industrial glazing, roofing, skylights, safety guards, and partitions. Their formability allows cold bending as well as thermoforming, adapting to diverse design and structural requirements. Available in multiple thicknesses, finishes, and colors, they cater to both standard and custom project needs.

Easy and Efficient Installation

Installation is straightforward thanks to smooth, machine-cut edges. Sheets support both mechanical fastening and adhesive bonding methods, enabling rapid deployment and secure fitting. Their lightweight nature and recyclability contribute to easy handling and environmental responsibility.

FAQs of Polycarbonate Sheet:

Q: How are polycarbonate sheets with UV protection typically installed?

A: Polycarbonate sheets can be installed using either mechanical fasteners or adhesive bonding, thanks to their machine-cut smooth edges. The process is simple, and the light weight of the sheets further supports effortless handling and placement.Q: What benefits does UV protection provide for these polycarbonate sheets?

A: Co-extruded UV protection on one or both sides significantly extends the sheets lifespan, preventing discoloration and surface degradation caused by prolonged sun exposureespecially important for outdoor settings such as skylights and roofing.Q: Where can these polycarbonate sheets be effectively used?

A: They are ideal for industrial glazing, roofing, skylights, safety guards, and partitions. Their high impact strength and excellent chemical resistance make them suitable for diverse environments, both indoors and outdoors.Q: When is it advantageous to choose polycarbonate over glass for installations?

A: Polycarbonate sheets are preferable when high impact resistance, greater flexibility, and enhanced safety are critical. With impact strength over 200 times that of glass, negligible shrinkage, and better formability, they are optimal for environments with a higher risk of breakage or vibration.Q: What is the process for shaping or forming these sheets for custom applications?

A: The sheets support both cold bending and thermoforming, allowing users to create curved or uniquely shaped installations without sacrificing material strength or integrity. This adaptability accommodates various architectural and industrial requirements.Q: How does chemical resistance benefit industrial applications of these sheets?

A: Excellent resistance to acids and alkalis protects the material from corrosion and degradation in chemically active environments, ensuring longevity and reducing maintenance needs in sectors like factories, laboratories, and outdoor installations.Q: What makes these polycarbonate sheets environmentally friendly?

A: They are 100% recyclable, allowing end users and installers to contribute to sustainability initiatives by ensuring responsible disposal and reuse of material once its service life concludes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Polycarbonate Sheet Category

Polycarbonate Sheet

Surface Finish : Other, Smooth/Corrugated

Color : Other, Transparent/Brown

Product Type : Other , Polycarbonate Sheet

Material : Other, Polycarbonate

Standard Thickness : Varies

Length : Customizable

Polycarbonate Sheet

Surface Finish : Other, Glossy or Matte

Color : Other, Transparent or Bronze

Product Type : Other , Polycarbonate Sheet

Material : Other, Polycarbonate

Standard Thickness : Varies; typically 1mm to 6mm

Length : Variable depending on customization

|

EVEREST COMPOSITES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry